Estimate Inquiry

We will design your air qualityHumidifier

We will be the company that thinks of customers first and the company that customers are proud of first

EL Series

TOUCH SCREEN CONTROL

The all new touch screen controller is easy to navigate and contains the information the user needs

INNOVATIVE NETWORK INTEGRATION

Standard building automation support with integrated BACnets

CONDAIR STEAM CYLINDER

The Condair steam cylinder are reliable and proved, they last drastically longer than any competitor product. Cylinder and the auto-adaptive water control reduce waste water to a minimum

Technical data

| SPECIFICATION | EL 005 | EL 010 | EL 020 | EL 030 | EL 050 | EL 075 | EL 100 | EL 150 | EL 200 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity: lbs/hr | 1-5 | 2-10 | 4-20 | 6-30 | 10-50 | 15-75 | 20-100 | 30-150 | 40-200 |

| Capacity: kg/hr | 1-2 | 1-5 | 2-9 | 3-14 | 5-23 | 7-34 | 9-46 | 14-68 | 18-91 |

| Input KW max | 1.9 | 3.7 | 7.5 | 11.2 | 18.7 | 28.1 | 37.4 | 56.1 | 74.8 |

| Voltage | 100-120 | 208-600 | 208-600 | 208-600 | 208-600 | 208-600 | 208-600 | 208-600 | 208-600 |

| Phase | 1 | 1 | 1 and 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| No. of Cylinders | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 |

| Built-on Blower Pack | yes | yes | yes | yes | yes | yes | yes | no | no |

RS Series

INNOVATIVE NETWORK INTEGRATION

Standard building automation support with integrated BACnet and internet connectivity for remote factory diagnosis

SCALE MANAGEMENT

The minerals precipitated from the water are continuously and automatically separated and fed from the steam cylinder to the scale collector tank: Long operation times are guaranteed

TOUCH SCREEN CONTROL

The all new touch screen controller is easy to navigate and contains the information the user needs

Technical data

| Housing sizes | Small | Medium | Large | 2x Medium Mater-Slave | 3x Medium Mater-Slave | 3x Medium Mater-Slave | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product reference | RS 5 | RS | RS 10 | RS 16 | RS 20 | RS 24 | RS 30 | RS 40 | RS 50 | RS 60 | RS 80 | RS 50 | RS 60 | RS 80 | RS 100 | RS 120 | RS 140 | RS 160 | |

| Dimensions WxHxD | mm | 420 x 987 x 370 | 530 x 1,097 x 406 | 1,000 x 1,097 x 406 | 2x 530 x 1,097 x 406 | 3x 530 x 1,097 x 406 | 4x 530 x 1,097 x 406 | ||||||||||||

| Operating weight | kg | 40.2 | 65.8 | 132 | 131.6 | 197.4 | 263.2 | ||||||||||||

| Heating voltage | Maximum steam output | ||||||||||||||||||

| 400V 3Ph 50-60Hz | kg/h | 5.1 | 8.1 | 9.9 | 16.1 | 19.8 | 24.2 | 29.8 | 40.0 | 49.6 | 59.6 | 80.0 | 19.8 + 29.8 | 2x29.8 | 2x40.0 | 2x29.8 + 40.0 | 3x40.0 | 2x29.8 + 2x 40.0 | 4x40.0 |

| 230V 1Ph 50-60Hz | kg/h | 5.0 | 8.0 | 9.8 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Control voltage | 230V 1Ph 50-60Hz | ||||||||||||||||||

| Conformity | CE, VDE, SVE | ||||||||||||||||||

CP mini Series

Condair CP3mini PR for direct room humidification

The Condair CP3mini PR with built-in fan distributes the steam perfectly throughout the entire room. The flow direction can be set through adjustment of the louvers.

Condair CP3mini PD for duct humidification

The Condair CP3mini PD releases the steam directly into the duct via the steam hose and the manifold.

Technical data RC4 DC4

| NORDMANN RC 4 | NORDMANN DC 4 | |||

|---|---|---|---|---|

| Heating voltage | 230V1~/50..60Hz 240V1~/50..60Hz 200V2~/50..60Hz |

|||

| Steam output | 2 kg/h | 4 kg/h | 2 kg/h | 4 kg/h |

| Max. electrical output | 1.6 kW | 3.1 kW | 1.6 kW | 3.1 kW |

| Fan air volume | 22 mÂł/h | |||

| Sound pressure level | 37 dB(A) | |||

| Max. room sixe (guideline) | 200 mÂł | 400 mÂł | ||

| Operating weight empty | 6.2 kg | |||

| Operating weight filled | 11 kg | |||

| Dimension (W x H x D) | 265 mm x 650 mm x 175 mm | |||

| Control signals | on/off (24VDC), 0-5 VDC, 1-5 VDC, 0-10 VDC, 0.20mA, 4-20mA | |||

| Water quality | untreated drinking water with a conductivity of 125..1250ÎĽS/ě¸ | |||

| Admissible water pressure | 1..10 bar | |||

| Admissible water temperature | 1..40 °C | |||

| Admissible ambient temperature | 1..40 °C | |||

| Admissible ambient humidity | max. 75%rF | |||

| Admmissible duct air pressure | -0.8..0.8 kPa | |||

| Protection | IP20 | |||

| Conformity | CE, VDE, GOST | |||

RC = for direct room humidificationDC = for duct humidification

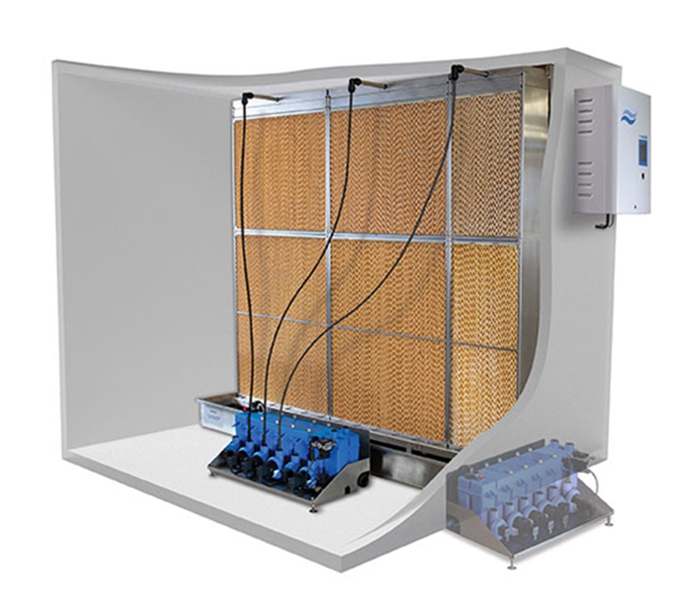

DL Series

Fit from smallest AHU Humidifier Section (W450, H450) to biggest (W8400, H4000)

Section length between 600 – 900 mm only, saving AHU section if compares with common high pressure systems

Ideal for retrofitting old washer and media humidifiers

Maximized evaporative area

Easy and fast to assembly

Technical data

| Dimensions / Weight | Type A (with booster pump) | Type B (with booster pump) |

|---|---|---|

| Absorption distance in AHU / duct (min-max) | 600-900mm | |

| Width AHU / duct (min-max) | 450-4,500mm | |

| Height AHU / duct (min-max) | 450-4,500mm | |

| Central unit HxWxD | 800 x 500 x 250mm | |

| Central unit weight | Approx. 54kg | Approx. 35kg |

| Control unit HxWxD | 450 x 315 x 1900mm | |

| Control unit weight | Approx. 14kg | |

| Hydraulic | ||

| Humidification capacity | 10-1,000kg/h | |

| Nozzle pressure | 3-7bar | |

| Nozzle sizes | 1.5, 2.5, 3.0, 4.0, 5.0kg/h @ 4bar | |

| Water quality requirement | Reverse osmosis water 0.5-15.0ÎĽS/cm | |

| Electric | ||

| Supply voltage / current control unit | 200-240VAC / 50-60Hz, max 6A | |

| Control booster pump motor | Continuous with freuency converter | |

| Control unit power consumption | 55-65VA | |

| Motor rating booster pump | Approx. 10VA per 10kg/h spray capacity | |

| Frequency converter | Yes | No |

| Control accuracy | 7 stems: ±4%RH 15 stems: ±2%RH 31 stems: ±2%RH |

7 stems: ±4%RH 15 stems: ±2%RH 31 stems: ±2%RH |

| Communication | ||

| Remote poerating & fault indication board | Yes | |

| Modbus RTU | Yes | |

| BACnet IP and BACnet MSTP slave mode | Yes | |

| Air | ||

| Pressure drop (2m/s) | Approx. 40Pa | |

| Max. air velocity | 3m/s without droplet eliminator. 4m/s with droplet eliminator | |

| Air finter quality before humidifier | F7 (EU7) or better | |

| Max. recommended air temp | 60°C (before humidifier) | |

Larger units available on demand. Higher temperatures available on demand. Control accuracy may vary depending on various external factors, e.g. temperature.

ME Series

Innovative hydraulic design can be installed inside or outside the AHU

Increased focus on low energy and high efficient buildings

Suitable for a wide range of applications

Significant reduction in energy consumption

Quiet operation, with long-life components

Stage control as standard

Wide range of install, hygiene, and communication options

Modular design with built in redundancy

Technical data

| Admissible water supply pressure PSI (bar) | Admissible water temp F (°C) | Power supply (Vac / Ph / Hz) | Power consumption (W) | Control panel IP rating | Water connections Inlet / Outlet in (mm) |

|---|---|---|---|---|---|

| 14.5-72.5 (1-5) | 41-68 (5-20) | 110-250 / 1 / 50/60 | 85-278 | IP2X | 5/8" / 1-1/8" (15 / 28) |

| Material Composition | Monded glass fiber media with anti-microbial impregnation |

|---|---|

| Certifiaction | UI900 |

| Dry Weight | 3.43 lb/ft3 (55 kg/m3) |

| Wet Weight | 9.67 lb/ft3 (155 kg/m3) |

| Recommended Water Flow Rate | Recommended min. 2 times the required evaporation rate |

| Maximum Media face Velocity | 689 fpm (3.5 m/s wighout droplet separator) 886 fpm (4.5 m/s with droplet separator |

| Maximum Air Temerature | 140 °F (60°C) |

| Maximum Water Temperature | 68 °F (20°C) |

ABS Series

Versatile

· 120 or 360 degree spray angle

· Wall or ceiling mounted

Most hygienic of its kind

· Electronical controlled rinsing and small reservoir

· Cyclic descaling process every 30 seconds guarantees no stagnant water

Precise adaptation to ambient conditions

· On/off or 0 – 10V control signal

Easy to install

· Connect to water mains

Technical data

| Condair ABS3 120 Condair ABS3 460 |

|

| Capacity of Humidification | 1.0…6.5 l/h |

| Air flow | 280 mÂł/h |

| Power consumption 230V / FN | 230 W |

| Power consumption 115V / FN | 230 W |

| Water quantity | 0.055 l |

| Operating temperature | +1…35°C, 0…100% H.R. (opcional -2°C) |

| Pressure in the water connection | 1…10 bar |

RO System

System characteristics

Reduction of scale and other minerals down to 1-3%

Maximal flexibility - complete standalone device or separate components for the configuration of complex individual solutiorns

perfect integration in systems with condair RS humidifiers

Technical data

| Contair RO-A | 40 | 100 | 200 | 300 |

|---|---|---|---|---|

| Permeate (L/h) @ 5°C and 2bar(41°F and 29 PSI) | 40(255 gpd) | 100(635 gpd) | 200(1270 gpd) | 300(1900 gpd) |

| Permeate (L/h) @ 15°C and 2bar (59°F and 29 PSI) | 70(445 gpd) | 140(890 gpd) | 300(1900 gpd) | 400(2535 gpd) |

| Max Permeate flow/day (mÂł/d) | 1.68 | 3.36 | 7.2 | 9.6 |

| Tank size L (gal) | 18 (4.75) | 18 (4.75) | 132 (35) | 132 (35) |

| Recovery hard water | 50% | |||

| Recovery hard water | 70% | |||

| Inlet pressure | 1.5-6 bar (21.8-87.0 PSI) | |||

| Water temperature | 5-20°C (41-68°F) | |||

| Salt rejection rate | 95-98% | |||

| Power supply | 120 V / 1 ~ / 60 Hz | |||

| Power consumption (W) | 600 | |||

| Connection and dimension | ||||

| Inlet water | 3/4" NPT | |||

| Permeate | 3/4" NPT | |||

| Drain | 9 mm (0.35") | |||

| Dimensions (H x D x W) | 815mm x 572mm x 485mm (32.1" x 22.5" x 19.1") | |||