Estimate Inquiry

We will design your air qualityClean Room Equipment

We will be the company that thinks of customers first and the company that customers are proud of first

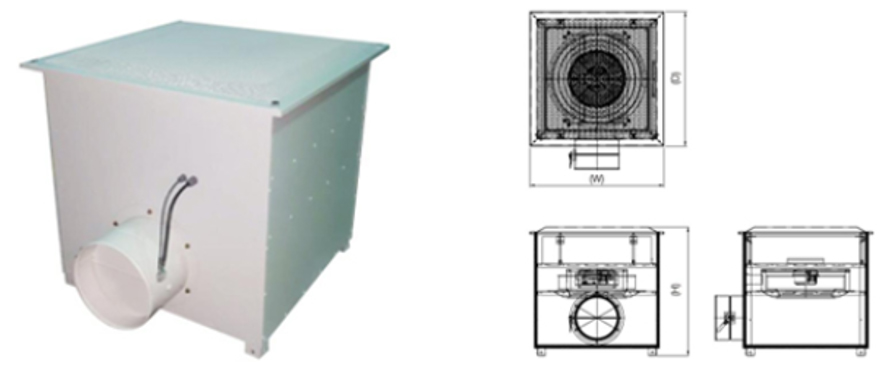

Blower Filter Unit (BFU)

There is a filter box inside the BFU, and a blower is installed in it to prevent the HEPA Filter static pressure loss. Therefore, it can be installed independently to improve cleanliness. It is possible to configure a system that can reduce the static pressure of the blower of each equipment by connecting the air handling unit (AHU) or precision air conditioner with a duct. It is mainly used in cleanliness conditions of less than Class 10,000, and it can be manufactured to automatically increase the rotational speed using a BLDC motor when the filter is contaminated.

Inverter type

Application field: Industrial clean room (ICR)

| Model | Dimension (WxDxH) | Filter size (WxLxT) | Electrical Specification (PxVxHz) |

Power consumption (W) |

Air Volume (CMM) |

Noise (dB(A)) |

|---|---|---|---|---|---|---|

| BF-BD432-610-610 | 750 x 750 x 680 | 610 x 610 x 150 | 1 x 220 x 60 | Under 113 | 17 / 15 / 12 | Under 62 |

| BF-BD432-610-762 | 750 x 902 x 810 | 610 x 762 x 150 | 1 x 220 x 60 | Under 400 | 19 / 17 / 14 | Under 65 |

| BF-BD432-610-915 | 750 x 1055 x 810 | 610 x 915 x 150 | 1 x 220 x 60 | Under 400 | 21 / 18 / 15 | Under 65 |

Main control unit (MCU)

Option

| Power specification | Rated input voltage: single-phase AC 220V, 50/60Hz |

|---|---|

| Current consumption: 250mA or less | |

| Rated operating voltage: DC 5.0V/A | |

| Cooling type | Air Cooled type |

| Forced ventilation is required when installing in a confined space | |

| Communication type | Specification: RS-485 Multi-drop 32Point |

| Connector: Modular Jack 6p4c RJ11 | |

| Features | Control and monitor up to 32 units |

| Individual and group operation status and control are possible | |

| LED error indication when an alarm occurs |

Local control unit (LCU)

Provision

| Power specification | Rated input voltage: single-phase AC 220V, 50/60Hz |

|---|---|

| Communication type | Specification: RS-485 Multi-drop 32Point |

| Features | Controller for exclusive use of BLDC motor |

| Alarm display function | |

| Overcurrent detection, short circuit detection between motor wires | |

| Over speed detection | |

| Remote control through communication | |

| Fan speed control (Linear control) |

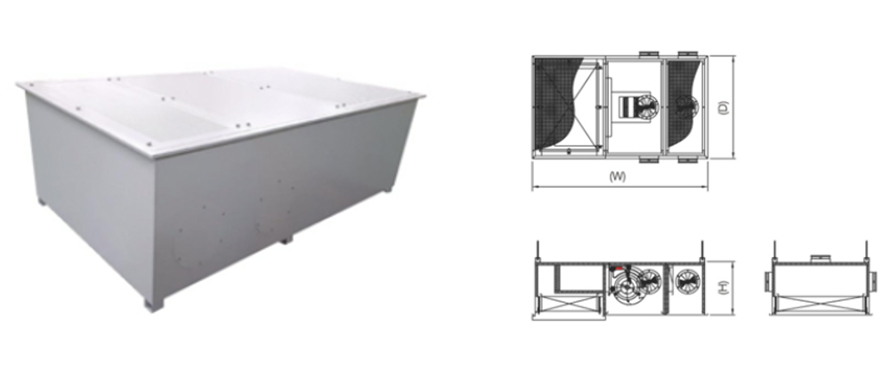

Medical Clean Unit (MCU)

Medical Clean Unit is a product manufactured and installed for the purpose of maintaining cleanliness necessary to create a clean and comfortable indoor environment to maintain the health of patients such as operating rooms, isolation rooms, and intensive care units of hospitals. According to the global trend, low-noise and low-power products that are differentiated from the existing ones are being demanded for a comfortable life, environment-friendly, and low-energy hospital facilities for occupants. We launched a differentiated low-noise, low-energy Medical Clean Unit through ceaseless efforts to meet the needs of these customers and through continuous research and development, and we want to provide the best products to build better clean room facilities. The biggest feature of the product is the ability to select and use the air volume suitable for the user's indoor environment, and also prevent the decrease in cleanliness due to the air volume reduction due to contamination of the HEPA filter.

Inverter type

Use

Bio Clean Room (BCR)-operating room, intensive care unit, positive pressure isolation room, negative pressure separation room, laboratory, etc.

| Model | Dimension (WxDxH) | Filter size (WxLxT) | Power Specification (PxVxHz) |

Power consumption (W) |

Air Volume (CMM) |

Noise (dB(A)) |

|---|---|---|---|---|---|---|

| MC-610-610-F150-R | 1810 x 755 x 550 | 610 x 610 x 150 | 1 x 220 x 60 | Under 140 | 17 / 15 / 12 | Under 45 |

| MC-610-762-F150-R | 1810 x 907 x 550 | 610 x 762 x 150 | 1 x 220 x 60 | Under 180 | 19 / 17 / 14 | Under 46 |

| MC-610-915-F150-R | 1810 x 1060 x 550 | 610 x 915 x 150 | 1 x 220 x 60 | Under 214 | 21 / 18 / 15 | Under 48 |

| MC-610-1220-F150-R | 1810 x 1365 x 550 | 610 x 1220 x 150 | 1 x 220 x 60 | Under 220 | 23 / 19 / 15 | Under 48 |

Simple control using RS-485 communication

The new MCU is a product that can be used by connecting to a clean room controller without a separate Local Control Unit (LCU) by using the RS-485 communication output provided from the self-developed embedded PCB. Since a separate LCU is not required, cost reduction can be expected, and basic functions provided by the built-in PCB include On/Off, air volume control, and group control.

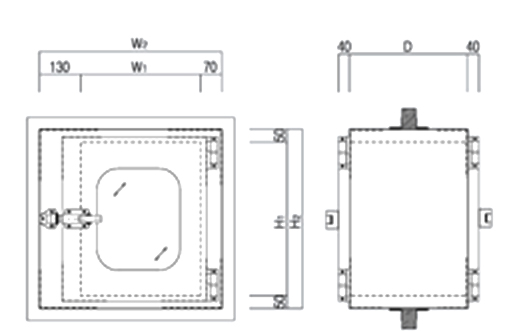

Pass Box

To prevent the dust and other bacteria from be carried in and keep the cleanliness effectively, it is most important to restrict and minimize the movement and the entry of the people from outside. Pass Box is one of clean units which you carry in and out goods while maintaining a purification class in clean room. Pass Box is to be placed at the boundary between clean rooms to prevents inhalation of contaminated air.

Standards Pass Box

The standard Pass Box is the most widely used for clean rooms. There is an interlock device that does not open the other door when one door is opened. The sterilizing Pass Box has a function of sterilizing the surface of the item with an ultraviolet lamp inside.

Air Shower type Pass Box

The Air Shower type Pass Box removes dust particles adhering to the surface by blasting clean air at a wind speed of 25 m/s or more per second to incoming goods. After the contaminated air is purged from the suction port through the pre-filter and HEPA filter, it is circulated through the discharge nozzle. It is also possible to attach a bowler to the bottom of the unit to facilitate movement when carrying goods.

| Dimension | |||||

|---|---|---|---|---|---|

| Model | W | W1H | H | H1 | D |

| ARPB-554 | 650 | 500 | 560 | 500 | 400 |

| ARPB-556 | 650 | 500 | 560 | 500 | 600 |

| ARPB-574 | 650 | 500 | 760 | 700 | 400 |

| ARPB-576 | 650 | 500 | 760 | 700 | 600 |

| ARPB-754 | 850 | 700 | 560 | 500 | 400 |

| ARPB-756 | 850 | 700 | 560 | 500 | 600 |

| Specification | ||

|---|---|---|

| Structure | Main body: Steel plate being baked finish painting or SUS 304 | |

| Floor: SUS 304 | ||

| Disply window: colorless transparent glass | ||

| Case Color | Standard color; Beige (Could be changed by order) | |

| Type | N type: No interlock | B type: Buzzer included |

| M type: Interlock included | L type: Lamp included | |

| I type: Intercom included | ||

| UV type: Sterilization lamp included | ||

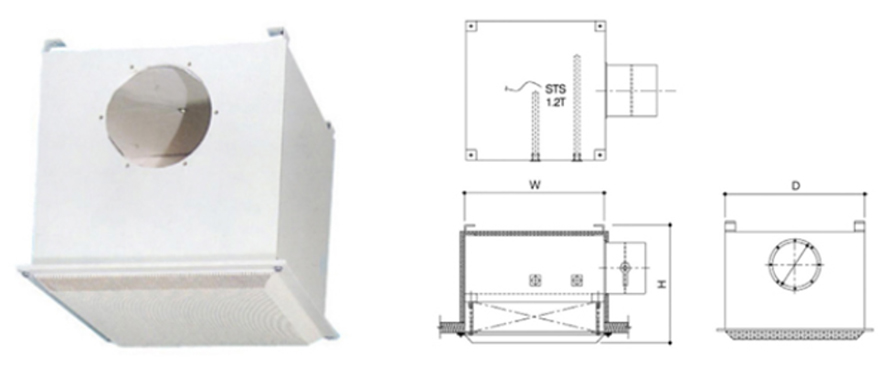

HEPA Box

The cleanliness level of a clean room greatly influences the performance of the clean room by the collection efficiency and ventilation frequency of HEPA, that is, the attachment method and number of installations. In particular, HEPA has a high efficiency of 99.97 ~ 99.99% of 0.3㎛ particles, so if there is a fine gap in the HEPA Box, it does not exhibit sufficient performance. Our HEPA Box is manufactured as a complete and reasonable box by special bonding method and welding based on our achievements and experiences.

| Model | HEPA Filter size (WxLxT) |

Air Volume (mÂł/min.) |

HEPA Box size | ||

|---|---|---|---|---|---|

| W | D | H | |||

| ARHF-1011 | 305 x 305 x 150 | 4 | 375 | 375 | 450 |

| ARHF-1012 | 610 x 305 x 150 | 8 | 680 | 375 | 450 |

| ARHF-1013 | 610 x 610 x 150 | 17 | 680 | 680 | 450 |

| ARHF-1014 | 610 x 610 x 292 | 32 | 680 | 680 | 550 |

| ARHF-1015 | 640 x 760 x 150 | 20 | 680 | 830 | 450 |

| ARHF-1016 | 640 x 760 x 292 | 40 | 680 | 830 | 550 |

| ARHF-1017 | 610 x 915 x 150 | 25 | 680 | 990 | 450 |

| ARHF-1018 | 610 x 915 x 292 | 50 | 680 | 990 | 550 |

| ARHF-1019 | 610 x 1220 x 180 | 32 | 680 | 1320 | 550 |

| ARHF-1020 | 610 x 1220 x 292 | 60 | 680 | 1320 | 600 |

Air Shower

In the Clean Room, Bio Clean Room such as the most clean atmosphere, the main source for the dust and the bacterium is the people's entry. Before entering to the inside of the place, the man should remove the particle attached on the surface of the clothes by blowing from the high-speed-clean air(25m/sec). Furthermore, the people's entry is restricted and it also have the good effects on the Air Shower which play a role in a spare room and prevent the open air from going inside

Features

1.By blowing and letting the strong air pass through the HEPA Filter, the developed fan for the Air Shower removes the dust, bacterium effectively which are attached on the surface of the clothes caused by Jet Nozzle.(0.3㎛ particle, efficiency more than 99.97%)

2. It prevents the air from the contamination from outside and maintain the pressure as the high-pressure by the clean air passing through the HEPA Filter. Thus, it keeps the entire cleanliness level and acquires the perfect clean effect.

3. The fan operates when the people enter inside and the function of operating time is locked inside of the clean room’s door and the configuring time is interlock systematized not to be entered.

4. The shower time can be adjusted by the Timer(5~30 Sec.)

5. In the Shower Room, it is required to move the body for touching of the air to the all body, and at least the body should be twisted more than 2 times thoroughly, and if the distance between the arm and the body is more than 10cm, the effectiveness will be improved.

| Specification | ||||

|---|---|---|---|---|

| Section | ARAS-752A | ARAS-752B | ARAS-1402 | |

| Performance | Dust collection efficiency | Main body: Steel plate being baked finish painting or SUS 304 | ||

| Jet air volume | 24CMM | 12CMM | 48CMM | |

| Number of purification | 120 times/hour | |||

| Nozzle | 12pcs | 6pcs | 24pcs | |

| Interior lighting | 20WĂ—1Set | 20WĂ—2Set | ||

| Power Consumption | (When operating Air Shower) 1645VA |

845VA | 3520VA | |

| Structure and material | Main body | Stainless and steel plate being baked finish painting | ||

| Floor | Adhesive mat | |||

| Filter material | PRE Filter | Non-woven | ||

| Main Filter | HEPA(610Ă—610Ă—150) | |||

| Control switch | Switch for air jet (Automatically and manually adjustable control) | |||

| Switchs for blowers and lighting | ||||

| Power | AC 220V / 300V 3Ph 60Hz | |||

| Door size | 770 mm | 1400 mm | ||

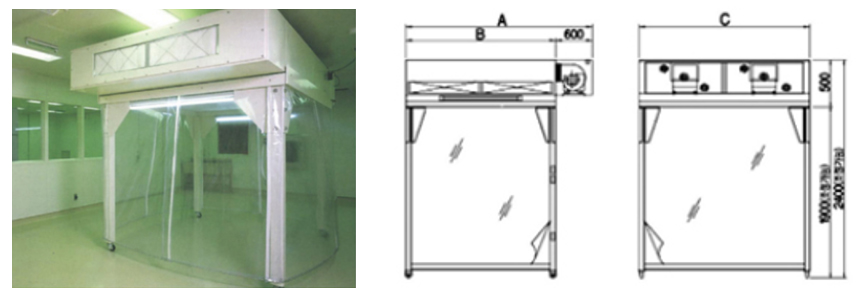

Clean Booth

Clean Booth is a structure with HEPA filter built-in on top and surrounded by vinyl curtains on all sides. There are fixed ceiling type and mobile type, and it is vertical laminar flow type clean room which can provide high cleanliness up to Class 100. Since a little positive pressure is maintained in the Clean Booth, external air does not enter, so you can always maintain high cleanliness.

| Dimension | |||

|---|---|---|---|

| Type | ARCB-100 | ARCB-200 | ARCB-300 |

| A | 1600 | 1600 | 2100 |

| B | 1000 | 1000 | 1500 |

| C | 1500 | 2000 | 2000 |

| Specification | ||||

|---|---|---|---|---|

| Section | ARAS-752A | ARAS-752B | ARAS-1402 | |

| Dust collection efficiency | Â 0.3ÎĽm particle, over 99.97% (D.O.P Test) | |||

| Blowing air speed | Over 0.35m/s | |||

| Circulation air volume | 36CMM | 48CMM | 96CMM | |

| Filter | PRE Filter | Over A.F.I 85% | ||

| HEPA Filter | Over 0.3ÎĽm 99.97% (D.O.P Test) | |||

| Structure and material | Unit | Steel plate being baked finish painting | ||

| Side plate | Colorless transparent glass or acryl | |||

| Front plate | Over Vinyl 0.5mm (Thikness) | |||

| Filter material | PRE Filter | Non-woven | ||

| HEPA Filter | Over 0.3ÎĽm 99.97% (D.O.P Test) | |||

| Color | Ivory | |||

| Fluorescent lamp | 40W x 2pcs | 40W x 3pcs | 40W x 4pcs | |

| Power | AC 220V 3Ph 60Hz | |||